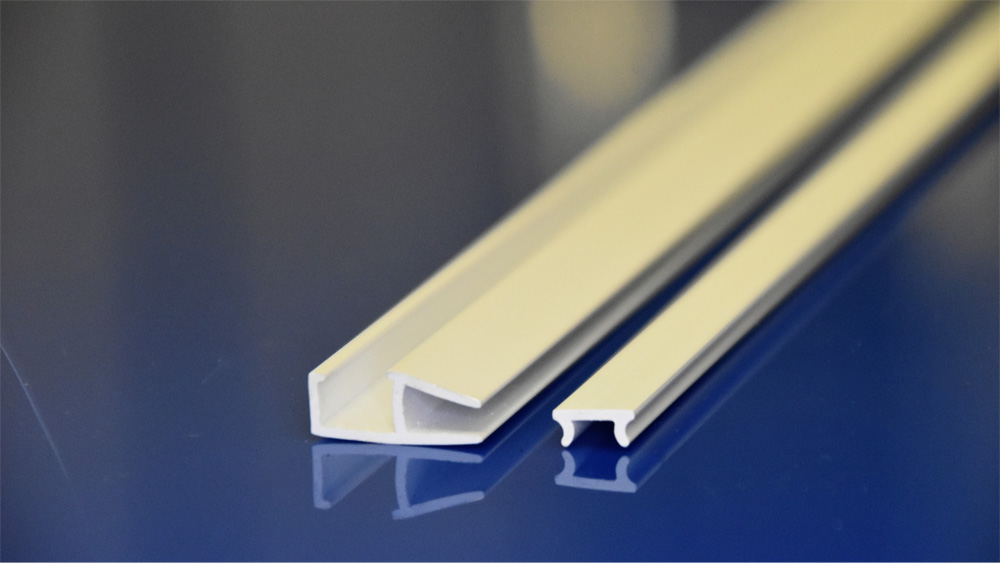

Easyfix Superglaze – 2 Part Rigid Capping

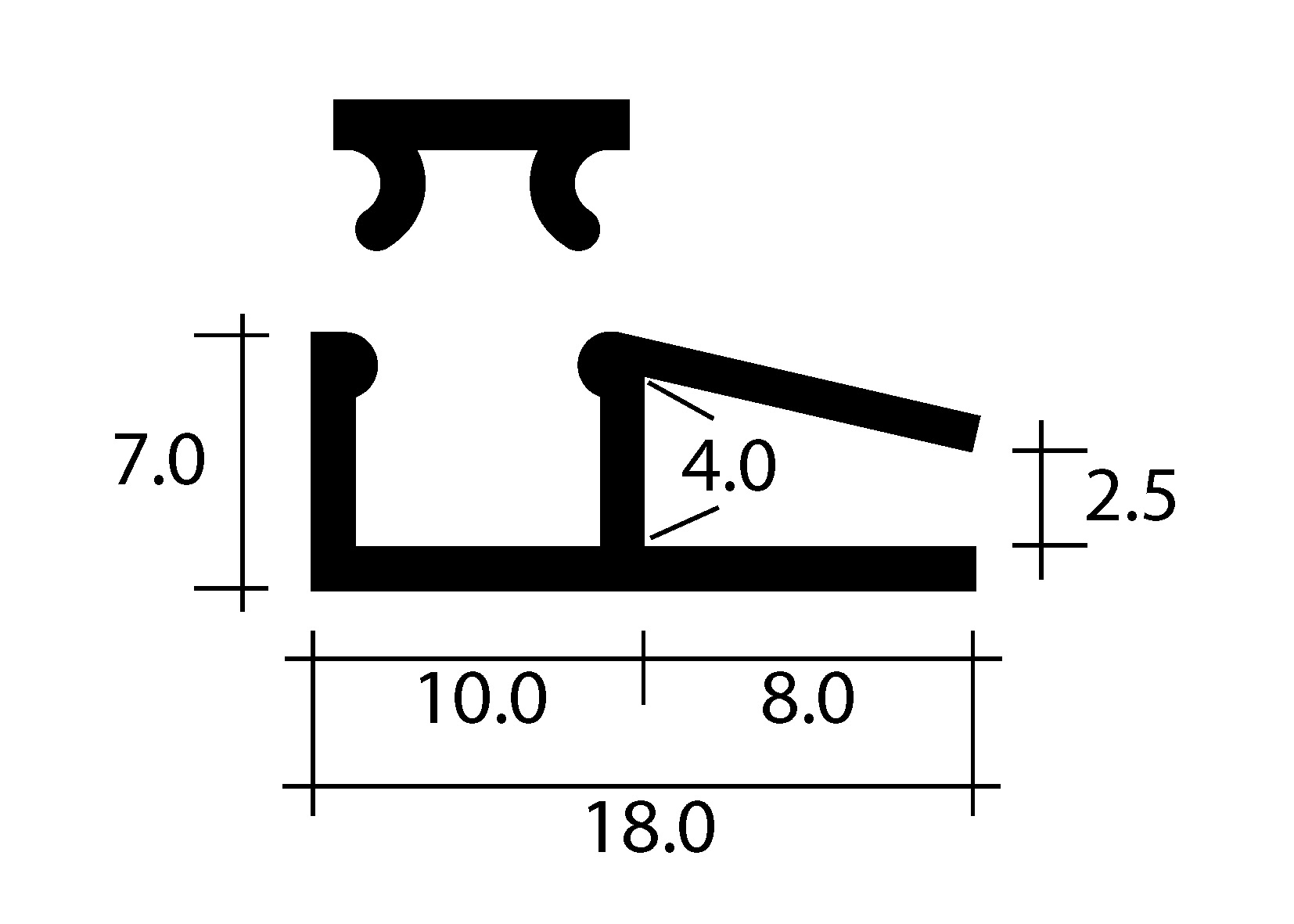

Superglaze is a cost effective, screw down secondary glazing system comprising a rigid PVC moulding to edge a 3 or 4mm plastic sheet or a glass panel. The moulding can be mitred at the corners, then fixed to the frame with screws through the open fixing channel. A cover strip is then snapped into place concealing the fixing screws resulting in a neat, unobtrusive appearance. We can supply the cut-to-size Polycarbonate sheets but for glass you will need to contact a local glazier for advice and pricing.

The insulation provided by Superglaze is effective for both heat retention and external noise reduction. The screw down nature of Superglaze makes it an ideal glazing solution for doors and skylights. Made from a UV stable PVC, Superglaze is therefore suitable for fitting both externally and internally, and can be unscrewed and stored during the summer if required, before being re-attached for the next winter.

Where a window surround is not flat or has rough surfaces, Superglaze can be installed with DE901 foam draught excluder stuck to the underside (covering the screw holes) before screwing it into place. The foam will therefore help even out undulations and create the thermal seal necessary for effective heat and noise insulation.

To add opaque film to your outer windows, as a neat alternative to net curtains, you can via our Privacy Frost Window Film page. This cost-effective new product is easy to fit.

Tools required are a fine toothed saw, mitre block, tape measure, bradawl and screwdriver.

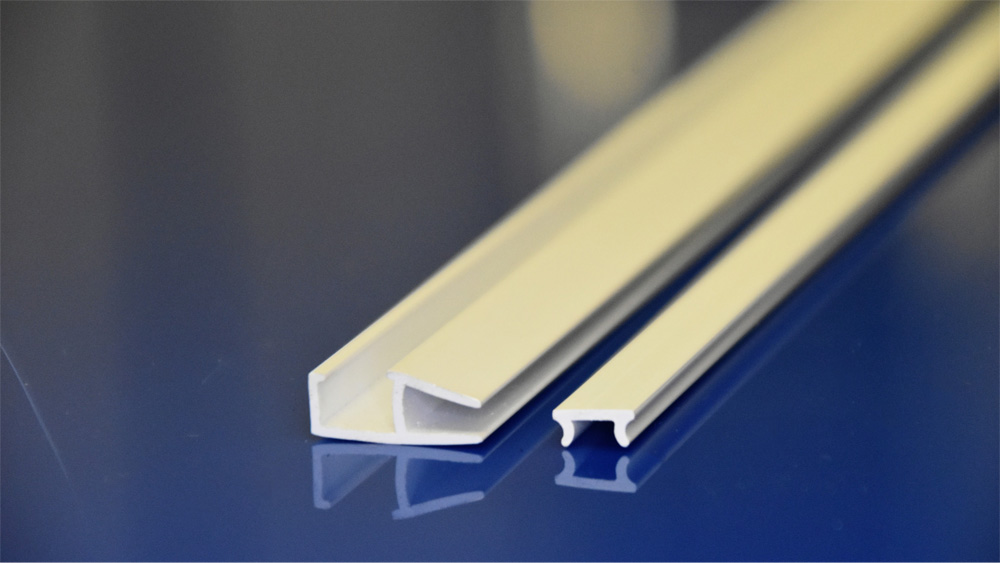

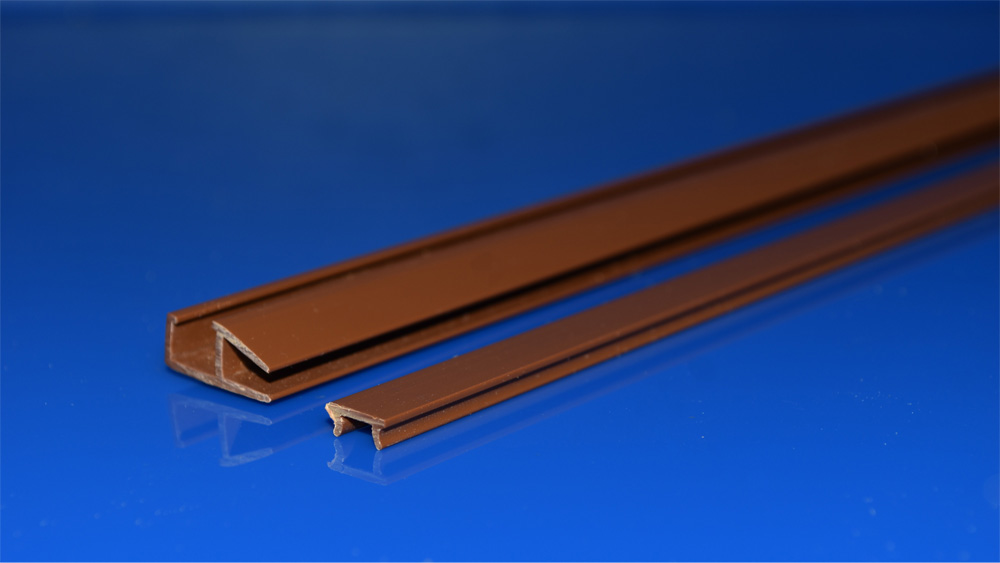

Superglaze can be purchased in 2.44m or 1.22m lengths in White or Brown and are either sold individually or in bulk packs of 10 lengths. Mitre beads are supplied with each lengths to insert into the edging when cutting to avoid chipping.

Suitable screws can also be provided but are ordered separately in packs of 100.

- Measure the window/frame area between where the inside edge of the Superglaze will sit (vertical = A, horizontal = B), ensuring at least 20mm mounting space on all sides.

- Add 16mm to both A & B to determine sheet size. This will create a pane overlap with the frame of 8mm on all sides to be held within the Superglaze base.

- For the Superglaze lengths you require 2 × (A + 39mm) + 2 × (B + 39mm).

- You will need approximately 6 screws per metre and we recommend 2.9mm x 13mm long self-tapping screws which can be purchased separately in packs of 100.

- Snap the cover strip into the base section.

- Measure the side of the glazing pane and add 23mm and cut this length of Superglaze squarely, repeat for all four sides.

- Insert the mitre bead and using the outer corner as reference cut a 45 degree mitre on each end using the mitre block and fine toothed saw, repeat for all lengths.

- Remove the mitre bead and cover strip ensuring you mark each base and cover strip to pair up again later.

- Where require peel a little of the protective film back from each edge and fit the base section along each edge pane starting at one end and easing on bit by bit to match up the mitred corners. If a bit tight dab a little washing up liquid to help ease the edging into position.

- If the fit is too loose at this point you can trim a little extra off the mitred ends as required, be sure to fit the cover strip back into place before doing so.

- You can now remove the protective film from rear side of the polycarbonate sheet and clean the pane.

- When the pane is fully dry offer up the pane to the correct position on the frame and fix in place with the suitable screws using a bradawl to create a pilot hole before screwing in place. We recommend starting with the bottom edge.

- Finally replace all cover strips to complete the installation. Always insert the inside leg and then press down and toward the outside leg, do not force with a mallet or hammer.

Superglaze Screws are 2.9mm x 13mm long self-tapping screws in packs of 100.

Mitre blocks are available to purchase to help cut the 45 degree ends required for the picture frame finish.

Surface Preparation Wipes can be used to clean and degrease any surfaces before sticking the tapes in place.

Antistatic Spray can be used to diffuse the static charge on the sheet when the film have been removed to help prevent the attraction of dust and particles from the air.

Microfibre cloths can be used to clean the sheets without scratching the glazing panels.

Clipglaze comprises a flexible edging that is fitted around the edge of the sheet and then held in place with turnbuckle clips which are screwed into the frame.

Why are small lengths of plastic for?

These are used to insert into the capping before mitring the corner. The plastic bead mimics the thickness of the plastic sheet, ensuring the angle of the mitre is accurate. You cut through both the Superglaze and the bead, before removing the bead and fitting on the Superglaze on the sheet.